Precision and power on 14,000 square metres

The technical know-how of our employees is perfectly complemented by a highly modern train of machines.

We are firmly convinced that we can only persist as an innovation and quality leader if we consistently focus on two points. Delivering the best quality requires highly motivated employees with excellent technical skills and extensive creative freedom as well as a highly innovative train of machines.

We fabricate our products with the following machine types in various dimensions, among others:

• Travelling column milling machines

• Gantry milling machines

• Horizontal centres

• Lathes

• Processing centres

In steel construction we work with gantry robots and robot cells among others. Here and also in manual welding, we employ welding specialists with excellent training who hold the proof of suitability certificate according to DIN 18800.

As experts in the fields of mechanical engineering and automation technology, we also pursue the continuous further development of existing systems in our manufacturing sector. We have already realised a variety of fixtures, delivery systems and machine adaptations for the continuous optimisation of processes and quality. If you stop getting better, you stop being good.

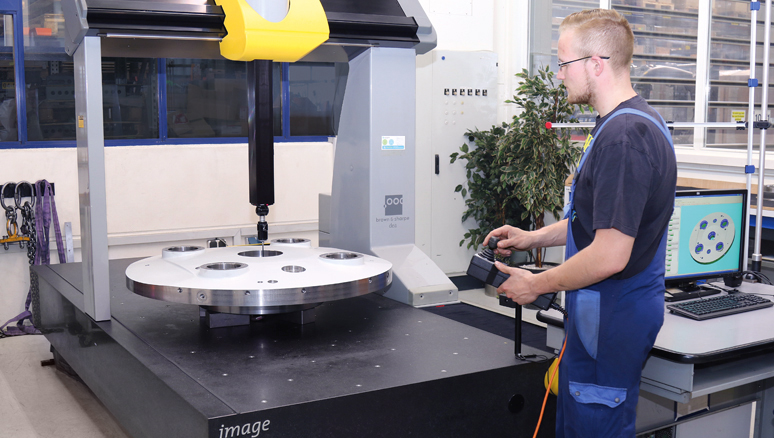

In addition to a corresponding layout, the best base materials and excellence in production, Demmeler guarantees the best quality in the market through quality assurance equipped among other things with 3D coordinate measuring machines and optical measuring instruments. Naturally inspections and measurements are performed in air-conditioned measuring rooms in order to ensure that the corresponding tolerances are met.

Overview Machinery

Milling

Multiple vertical and horizontal gantry processing centres

- Traverse paths up to: X 11,000 mm, Y 4,500 mm, Z 1,500 mm

- Distance between uprights up to 3,150 mm

- Spindle drive output up to 80 kW

- 180x tool changer with SK 50 and HSK 63

- 300x robot-based tool changer with HSK 100

- Orthogonal high-speed milling head 18,000 RPM

- and automatic milling head changeover

- 5-sided processing

- 2x pallet changer

- Renishaw touch probe

- High-pressure interior cooling 30 bar

Various travelling column processing centres

- Traverse paths up to: X 26,000 mm, Y 7,000 mm, Z 2,000 mm

- Spindle drive output up to 50 kW

- Multi-station processing

- Universal head for 5-sided processing

- Includes NC rotary table up to 2,500 x 2,500 mm with a load capacity of up to 60 tons as additional axis

- 160x tool changer with HKS 100

- Good economic efficiency through best dynamics and rapid motion up to 36 m/min.

Bed-type milling machine

- Traverse paths up to: X 3,500 mm, Y 1,400 mm, Z 1,200 mm

- Spindle drive output 35 kW

- Universal head for 5-sided processing

- 200x robot-based tool changer with SK 50

- 2x pallet changer

- Good economic efficiency through best dynamics and rapid motion up to 30 m/min.

- Renishaw touch probe

Various horizontal, flexible and linked processing centres

- Traverse paths up to: X 2,500 mm, Y 1,800 mm, Z 1,600 mm

- Spindle drive output up to 40 kW/up to 10,000 RPM, 1,200 Nm torque

- 240x tool changer with SK 50 and 280x robot-based tool changer with SK 50

- Pallet changeover system up to 4x:

- 2x pallet size: 2,400 x 1,800 mm

- 2x pallet size: 1,600 x 1,400 mm

- and 30x:

- pallet size 630 x 630 mm/800 x 630 mm (shuttle feed, 2 setup stations for setup in parallel with primary processing time)

- Work piece weights up to 10 tons

Vertical processing centre

- Traverse paths up to: X 510 mm, Y 400 mm, Z 500 mm

- Spindle drive output up to 25 kW/3,000 RPM

- 24x to 30x tool changer with SK 40

- 2x pallet changer

Several vertical CNC universal milling machines

- Traverse paths: X 500 mm, Y 500 mm, Z 400 mm

- Spindle drive output approx. 10 kW

- SK 40

Lathes

CNC dual-spindle lathe cell

- D 760 mm, D 420 mm, up to 1,500 mm turning length

- 8 axis

- 2 lathe spindles up to 30 kW and 4,000 RPM

- Universal lathe spindle: 18.5 kW and 12,000 RPM

- Suitable for complex turned/milled parts including toothing

CNC universal lathe

- Traverse paths Y +/– 30 mm

- Spindle drive output: 20 kW

- Max. diameter: 150 mm

- Max. turning length: 190 mm per side

- RPM range: 25 – 5,600 RPM per spindle

- Rapid motion: 30 m/min.

- 2 revolvers with 12 slots, each with 12 power-driven tools

- Maximum output per power-driven tool: 3.8 kW

- Bar loading system

CNC dual-spindle lathe cell

- Max. work piece dimensions: diameter: 250 mm/length: 350 mm

- With reverse side processing and power-driven tools

- 4-axis rotation

- Gantry robot system for chuck components

- Short bar loader up to max. diameter: 50 mm for bar components

CNC lathe

- Swing diameter over carriage: 300 mm

- Distance between centres: 1,200 mm

Several cycle-controlled and conventional lathes

- Swing diameter over carriage: 250 mm, turning length: 1,000 mm

- With digital display

Steel construction

Welding robot with 6 + 3 additional axes

- Welding robot gantry system with 20 m traverse path

- Two 6-axis welding robots

- Tandem welding system

- Various swivel manipulators

- Demmeler base rail system

- Multiple-station processing

40 modern welding stations

Equipped with Demmeler 3D clamping system

MIG/MAG/WIG welding systems

Continuous sandblasting line

12,000 x 2,500 x 600 mm

Cutting

Including modern high-bay racking with various CNC automatic band saws

Coating line

Dimensions 20,000 x 5,000 x 5,000

Drying capacity: 2 x 60 kW

Quality assurance

Quality assurance

3D coordinate measuring machine

CNC coordinate measuring machine

– Measuring path: X 2,200 mm, Y 120 mm, Z 1,200 mm

– Granite table: 3,170 x 1,400 mm

– Automated probe changer

– 2 air-conditioned measuring rooms

Granite plate/autocollimator/Leveltronic

3 autocollimators | Leveltronic | Niveltronic