Invest into the future – 5 benefits of the Demmeler clamping systems

1. Welding fixtures are a thing of the past – the future belongs to 3D economical clamping systems

No more fixture construction of yesteryear! Does your state-of-the art company also have certain production areas where it seems as though technology had almost come to a standstill? Then you have come to the right place! Demmeler offers you qualified advice in addition FREE OF CHARGE!

No more fixture construction of yesteryear! Does your state-of-the art company also have certain production areas where it seems as though technology had almost come to a standstill? Then you have come to the right place! Demmeler offers you qualified advice in addition FREE OF CHARGE!

Your ROI can be achieved faster than you think!

Investments must pay off! With Demmeler 3D clamping systems, you not only achieve your return on investment very quickly but also increase your productivity. Do your own calculation and check your equipment including its storage, maintenance, preparation before use times and equipping times.

Original Demmeler 3D-Clamping systems – Economical, flexible, patented, proven!

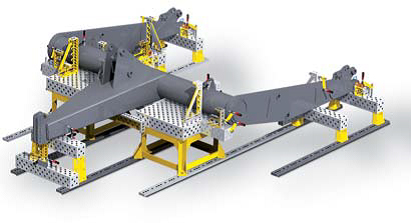

The Universal 3D work bench and welding table can meet all horizontal and vertical requirements. Precisely, quickly and in no time at all, you can erect your system with these modular parts: machine housing, racks, frames, crossbars, brackets, railings, stairs, doors, control cabinets, metal cladding panelling etc. Conventional devices, elaborate and cost-intensive, are therefore a thing of the past. This system, for every workpiece you process, allows you achieve quick, precise adjustment and fixing of the target dimensions. During the entire stapling and welding process, your individual weldments are clamped at the corresponding surfaces or points and thus are in the best possible position.

The Universal 3D work bench and welding table can meet all horizontal and vertical requirements. Precisely, quickly and in no time at all, you can erect your system with these modular parts: machine housing, racks, frames, crossbars, brackets, railings, stairs, doors, control cabinets, metal cladding panelling etc. Conventional devices, elaborate and cost-intensive, are therefore a thing of the past. This system, for every workpiece you process, allows you achieve quick, precise adjustment and fixing of the target dimensions. During the entire stapling and welding process, your individual weldments are clamped at the corresponding surfaces or points and thus are in the best possible position.

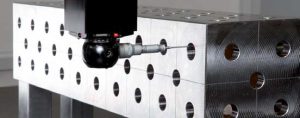

The sturdy, high loading-bearing 3-D work and welding table is machined on all 5 sides with a regular hole grid pattern.

As a result, all workpieces can be infinitely positioned and clamped by the appropriate clamping components of the system using the patented positioning and clamping bolts on the complete 3-D work and welding table. Several 3-D tables can be connected directly together on any of the 5 sides or spacers.

As a result, all workpieces can be infinitely positioned and clamped by the appropriate clamping components of the system using the patented positioning and clamping bolts on the complete 3-D work and welding table. Several 3-D tables can be connected directly together on any of the 5 sides or spacers.

This modular system fulfils a versatile function: Place, fasten and clamp. By means of CAD, reproducible virtual jigs can be very comfortably set up already in the planning process.

3D coordinate measuring machines, laser measuring systems and optical test equipment are used for this purpose to ensure the high precision requirements of the products. The 3D workbench and welding table only needs a light coating of antispatter agent or spray once a day for additional protection, to make it insensitive to dirt, scale, spatter and sand. Proven technology in practice, many times over.

3D coordinate measuring machines, laser measuring systems and optical test equipment are used for this purpose to ensure the high precision requirements of the products. The 3D workbench and welding table only needs a light coating of antispatter agent or spray once a day for additional protection, to make it insensitive to dirt, scale, spatter and sand. Proven technology in practice, many times over.

Beating the rest – with original Demmeler 3D concepts

2. Cost-efficient start – efficient and modular enlargement

The modularity of the Demmeler 3D clamping system allows you to start with a small welding table but still clamp XXL workpieces in the future.

You can arbitrarily extend your 3D welding table in all directions through the modular design.

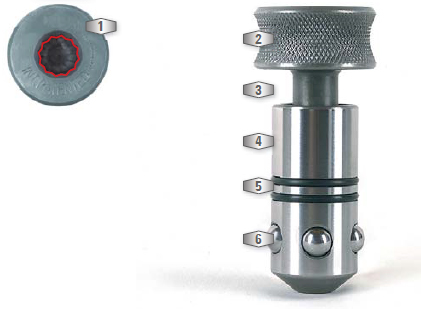

3. The ORIGINAL – often imitated but never duplicated patented quality

Your benefits:

- Highest clamping force with a large clamping stroke due to planetary gear effect

- Ergonomically knurled bolt head for fast one-hand operation

- With wide clamping ranges

- High quality, hardened steel; High precision through ground finish

- O-Rings prevent simultaneous rotation when tightening and at the same time clean the system bores.

- 5 clamping balls, which are mechanically secured against falling out!

Your benefits:

- Workpiece clamping true to position and location through differential compensation

- Tension tube can be replaced quickly; available in different lengths

- with adjustment ring for height fi xing

- Actuation type can be changed (Spindle, short boring spindle, quick-action clamping cylinder, pneumatic cylinder)

- Pressure plate can be exchanged when clamping other materials like e.g. stainless steel

- Intake by any system bore (self-clamping effect)

Your benefits:

- Handle with a special surface and rubberised inserts for rich and non-slip grip!

- Spindle with integral hexagonal surface for perfect clamping with standard straddle wrench!

- Modularity down to detail: The Demmeler clamping bush can be used in any system bore. This allows for a number of clamping options in a few simple steps!

- Clamping handle can be tilted up to 15 ° at full power transmission, therefore enough room for welding!

- Pressure plate can be exchanged and also be used in system bores as support or abutment surface. Standard for all System 28 screw clamps New thrust and support piece

Patented flagship solutions

Their patented and frequently award-winning 3D-clamping systems have established themselves as a worldwide industry standard. The system sizes D28 and D16 can be interconnected almost compatibly, thereby resulting in countless areas of application. The modular concept allows you to set up very complex and precise fixtures in the shortest possible time. With both systems, you achieve a high degree of economic efficiency for both individual pieces as well as series produced parts.

4. System sizes 28 and 16 – for individual demands

Our preferred system size 28 –

Our preferred system size 28 –

for everyday and large weldments

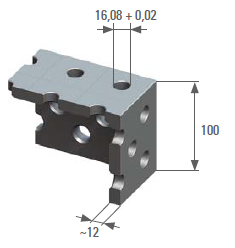

- Bores Ø 28

- Grid 100 x 100 mm

- Bore spacing 100 mm

- Table leg height 200 mm

- Material thickness approx. 25 mm

- For everyday and heavy weldments

Our system size 16 – for filigree requirements!

Our system size 16 – for filigree requirements!

- Bores Ø 16

- Grid 50 x 50 mm

- Bore spacing 50 mm

- Table leg height 100 mm

- Material thickness approx. 12 mm

- For easy clamping tasks, profiles up to 20 mm

5. Profi -, Expert- & EcoLine welding tables – three lines for every need

ProfiLine P28

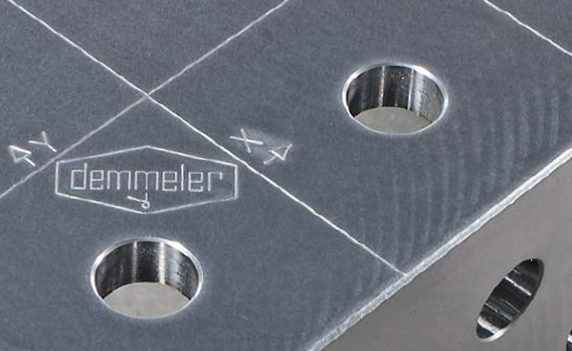

- … for playing in the higher league! 80 % more bores through the diagonal grid– thus, with additional clamping options

- 1 mm precision scaling completely integrated

- grid lines every 100 mm + numbering

- Axis indicators in x- and y-direction

- with high fi ns and strongly ribbed, hence high intrinsic stability

- Leg sleeves at the table feet prevent snagging snagging of welding cables and protect the thread from dirt

- stable M30 x 2 threaded foot spindle ± 30 mm adjustable

- Modularly expandable in all five directions over the entire

- length, width and height

- without metre rule, it is possible to very quickly erect accurate clamping jigs

- various foot type versions available

ExpertLine D28 / D16

- … sound technology for everyday use!

- 1 mm precision scaling completely integrated

- grid lines every 100 mm + numbering

- Axis indicators x, y

- with high fi ns and strongly ribbed, hence high intrinsic stability

- Leg sleeves at the table feet prevent snagging of welding cables and protect the thread from dirt

- stable M30 x 2 threaded foot spindle ± 30 mm adjustable

- Modularly expandable in all five directions over the entire length, width and height

- without metre rule, it is possible to very quickly erect accurate clamping jigs

- various foot type versions available

EcoLine E28 / E16

- … this is how inexpensive starting off can be!

- modular system design

- upward compatible with other Demmeler product lines

- quality accessories available

- Modularly expandable in all five directions over the entire length, width and height

- low-cost 3D welding tables and tools for beginners

- Table foot versions: Standard foot, heavy duty wheels