Demmeler as a company

The success story of the internationally successful family-owned company began when the 19-year old Ludwig Demmeler laid the foundation in 1961: In his small workshop, he worked as a subcontractor for nearby industrial businesses.

Already by 1990, DEMMELER set the standards on the market as the inventor of the 3D clamping system: Originally intended for the company’s own production, the device system proved to be a quantum leap in metal processing and today is an international industrial standard due to the many possible applications and combinations.

DEMMELER, managed in the second generation by Johannes Demmeler as the managing director since 2001, operates on more than 40,000 m² of floor space. At the same time, we remain true to our roots in Allgäu. After the relocation in 1989, we have been producing our products exclusively in Heimertingen. This commitment was also recognised by the Bavarian Ministry of Economic Affairs, which honoured Ludwig Demmeler for his entrepreneurial achievements by awarding him the Federal Cross of Merit.

The company’s growth was accompanied by several product developments, which were first produced only for their own production facilities. Put through their paces, they now deliver these products to customers worldwide. In addition to the 3D clamping system, these also include the turning, tilting and carousel rotary tables, as well as 3-axis manipulators, tool arenas and tool machine components.

The highest “made in Germany” quality

“Made in Germany” is now regarded as a seal of quality and a sign of quality. Demmeler develop and produce exclusively in Germany in order to continuously check and optimise production processes, i.e. in order to ensure the high quality of products.

Thanks to their steadily growing and highly specialised team, Demmeler products will continue to meet the needs of customers all over the world. The commitment of their employees has already resulted in a number of ground-breaking industry innovations.

Precision redefined

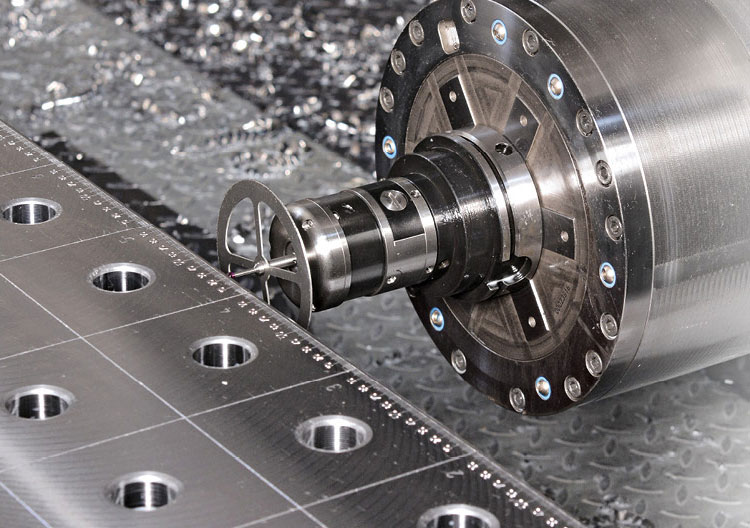

Demmeler set high standards for production, since it forms the basis for their excellent quality products. Only the best is good enough. Only materials from certified suppliers are used, which is a crucial requirement to consistently guarantee a consistently high production quality.

Ultimate precision is a key quality characteristic of products. That is why they place the utmost value on the dimensional accuracy of all parts that leave the plant. Demmeler rely on the latest generation of measuring tools and test systems: 3D coordinate measuring machines, laser measuring systems and optical test equipment.