For accuracy and reliability it’s Demmeler tables

With accuracy in fabrication and assembly a pressing issue for the welding industry, demmeler fixturing tables for assembly, testing and welding provide tight tolerances.

The system has enjoyed fast uptake by industries such as discrete manufacturing, mining, machining, welding, steel fixing, building, construction, electronics, defence and a host of other areas.

The modular Demmeler system offers features, benefits and capabilities not found in other standard fixturing methods, says Leussink Director, Mr Jason Leussink.

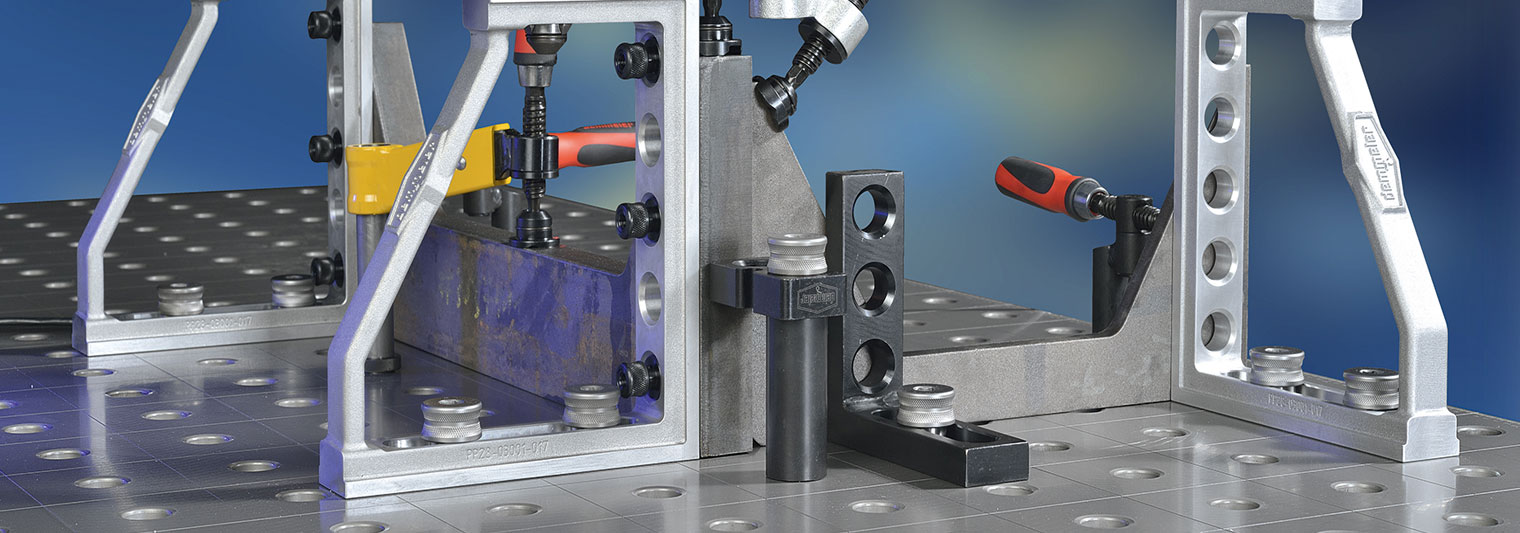

“The heart of the Demmeler system is the solid steel block-like work table designed to provide a sturdy platform for mounting weldments with a variety of angles, blocks and accessories”.

These work tables are made of heavily ribbed, high tensile, high strength steel, machined to very tight tolerances to ensure stability and flatness and are designed to be used alone or bolted together to accommodate larger work pieces.

Each work table is made with a grid pattern of 28-mm mounting holes, spaced on a 100-mm grid, across the face and four sides of the table. If closer spacing is required, sub plates with a double-density grid pattern also are available, with a grid spacing of 50mm x 50mm for mounting to the main tables.

An assortment of structural components and fixturing elements are used to construct tools with this system. Specialized positioning and clamping bolts are mounted through the holes and slots and when engaged, generate up to 3 tons of clamping force and will resist up to 25 tons of shear force.

For economic and precise positioning, clamping, tacking and welding of multipiece components, the modular demmeler fixturing system is “indispensable”, says Mr Leussink.

There are two modular table versions: the D16 and D28, each one coming with a work table featuring a precision grid pattern of bores on top and side machined surfaces for positioning and clamping connecting elements for assembly components.

Source: Industry Update, original article by Leussink Engineering